S G Iron Casting Manufacturer

Magna Industries Foundry Division is an IATF 16949:2016 and ISO 9001:2015 certified company, and part of the Samarth Magna Group. We are a leading manufacturer of medium to high-volume, small to medium-sized machined castings in SG Iron. As one of the top SG Iron Casting Manufacturers in India, we serve a wide range of industries, including hydraulic applications, EGR systems, power transmission, lifts & conveyors, and the automotive sector. Our clientele includes major players across these fields.

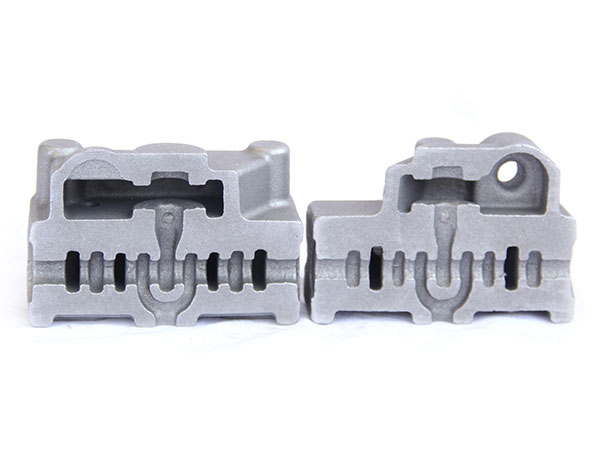

Our team, infrastructure, and processes are capable of producing intricate SG Iron (Ductile Iron) Castings with high precision. To meet the challenges of being a Ductile Iron Foundry in India, Magna Foundry leverages fast development capabilities, flexible manufacturing approaches, and robust supporting infrastructure. This enables us to offer a unique advantage in shortening lead times for both customers and end-users. Additionally, Magna Foundry is a leading SG Iron Foundry in India, with an in-house machining facility designed to cater to a wide range of weight, size, and volume requirements..

With our extensive capabilities, we are proud to be one of the leading Spheroidal Graphite Iron Castings in India manufacturers, committed to delivering top-quality solutions to our customers. As a rapidly growing SG Iron Casting Foundry in India, we continue to lead the way in producing high-performance castings for a diverse range of applications.

Our Shell Moulding Foundry Capability

Eco Friendly Infrastructure with Thermal Sand Reclamation

Our Products

Markets Served

- Hydraulic valves & Bodies- Fluid flow valves having critical internal passages

- Pumps- Oil/Water pumps and Impellers having thin fins

- Exhaust system- Parts that can withstand high tempratures like manifolds

- Power transmission- Turbochargers and Turbines

- Lifts & Elevators- Safety assemblies

- Dampers

- As cast Chain links for conveyors

- Other speciality areas- Thin walls(2mm), internally sound quality parts where safety is topmost priority, flexibility in part weight and volumes, ADI & CGI grade for special applications like forging replacements

Numerical Facts About Magna Foundry

Why Choose Us For SG Iron Castings?

Fast Component Development

Flexible Manufacturing: Weight & Volume

- Weight range- 1 kg to 40 kg

- Variety of grades of CI, SGI & SiMo

- Medium to High volumes

Reduced Lead Time

2 Decades of Experience

Fully Machined Components, Under One Roof

Delivery: On Time, Every Time

Robust QMS Implementation

Eco-friendly Infrastructure

Awards and Recognition